A couple years ago I built my own pull up station out of wood and pipe. I documented the process here on the blog. So far the pull up bar has held up very well so I thought I would expand on my outdoor body weight workout equipment by constructing a set of parallel bars using similar techniques.

Ok let’s first list everything I bought for the project, the total spent on materials came in just over $200. Everything was purchased at Home Depot.

2 – 10 foot sections of 1 1/2″ diameter galvanized pipe

4 – 8 foot long pressure treated 4×4’s

1 – 2 inch, ridiculously expensive ($29) wood boring drill bit

4 – 6 inch 9/16″ bolts, nuts and 8 washers

4 – 1 1/2″ PVC end caps

4 – 50 lb bags of quick set concrete

The first step was to decide how close to the pull up station I wanted to place the parallel bars. I decided 8 feet was a good distance and I used two of the 4×4’s to mark it. I wanted my supports for the parallel bars to be the same distance apart as the pull up station supports. (a little more than 4 feet) I then dug my first two holes with the post hole digger. I went approximately 30 inches deep, I wanted to have 5.5 feet of the post above ground.

I got the first two posts in the ground and level with each other. I measured level by putting a board across the top and throwing my level on it. I used another 4×4 on the ground to make sure the posts were square with each other, laying it against the side of the supports and making sure it was flush.

I put some of my heavy landscape stone on top of the top board to keep the two posts stationary. (in addition to some small back filling) I then cemented the first two posts in place since they would be my reference points for the next two posts. To cement a post in I filled the hole a third of the way with water, added concrete until it extended above the water, added another third of water, more concrete and then topped of the hole with water and the last third of concrete.

So far the process was going well, it was pretty much the exact same formula I used for the pull up station. Well adding two more supports multiplied the frustration level quite a bit.

After measuring my favorite dip station at the gym I knew I wanted the bars of my station to be about 25 inches apart. I also needed the second two supports to be parallel with each other, as well as parallel, square and equidistant with the first two supports. This proved to be much more challenging than expected.

It took me a ton of trial and error to get the last two posts in place. I’d get them level and then they wouldn’t be square. Or I get them square but then they weren’t 25 inches apart on center. I bet I spent a solid hour just f’ing around trying to get these final two posts as perfect as I could. You are trying to be precise with a hunk of wood in an open, sandy hole, it just isn’t that easy.

Finally I called the second set of posts as “Good nuf” and cemented them in place.

The first set of posts had been cemented for a couple hours at this point so it seemed safe to progress onto the hole drilling, pipe threading phase. I wanted to make sure that drilling into the top of the support did not significantly alter it’s position. To help ensure this I attached a board between the top of the first two supports temporarily to reenforce them.

It was then time to get the expensive drill bit out. The 2 inch bit was a perfect diameter for the 1.5″ pipe, allowing just enough clearance to slide the pipe in.

I eyeballed how high I wanted the hole to be by standing next to the post and lifting my hands up to where I could get up on the bar without jumping. It worked out to be about 8 inches below the top of the 66 inch post. I wanted to make sure the hole was not too close to the top of the post to make sure it didn’t weaken the wood and split.

Again I eyeballed center on the post, tried to keep my drill as level and straight as possible and started drilling. The bit seemed to be well worth the money I paid for it. It made a clean, quick hole in the 4×4 with little fuss. I had to go back and forth in the hole a few times to give me a fraction on an inch of additional clearance to make the pipe slide through easily.

To mark my second hole I extended the pipe to the second post, centered it on the post, put a level on it and then used a pencil to mark the bottom of the pipe. In retrospect this was a less than ideal technique. I would have been better served with a 2nd set of hands that could have drawn a complete outline of the pipe on the post.

I then lined up the bottom of the drill bit on the line, centered it up and drilled my second hole. When I tried to thread the pipe through the second hole I had great difficulty in doing so. I had to use the drill bit to shave extra off the inside of the hole before I could work the pipe all the way through.

When I looked at the far side of the second hole I saw what the problem was. Evidently when I drilled the second hole my trajectory was not perfect, the drill must have been angled slightly right and down. It’s a side effect of freehand drilling. The only way I know you could avoid this is by pre-drilling the holes on a drill press or using some sort of rig that you could attach to your drill.

So although it wasn’t perfect, I got the pipe through. It was time to do the other side. The first order of business was to make sure the second pipe was at the same height as the first. My method for doing this was holding my 4 foot level against the bottom of the first pipe, finding horizontal level and then marking that spot on the other post, that spot would be the bottom of my second set of holes. Again there may be better ways to do this but this is how I did it.

Learning from my errant drilling on the last hole, I did my best to stay as straight and level as I could with both holes on the left side of the station. I fared better on this side, unfortunately since the first pole was slightly off you could see a minor height variation on the right end. Oh well. I hopped on the right end and did a couple dips, I could hardly feel the height difference during the motion.

At first I was considering leaving the full 10 foot length of pipe intact. However I reconsidered when I realized having more pipe coming out the side with the bad holes just emphasized the slightly mismatched angle. I decided to have a shorter length of pipe extending from the right than the left. It will give me some variation in usefulness and make the right side stronger when using it for stuff like racking a barbell.

I chopped 2 feet off each pipe with my sawzall, leaving me 8 feet of pipe to work with. I threaded the pipes back through the holes and was now ready to bolt the pipes into place so they don’t move around. I used a 9/16″ metal drill bit to go through both the wood and pipe. I used my off hand to hold the pipe securely in place to keep it from spinning. After doing so I slid the bolt through with a washer on either side.

Next I tapped the PVC end caps onto the pipe to protect hands from sharp metal edges. The fit was snug enough that I didn’t need glue them on. The last thing I did was attach a wooden brace across the bottom of both sets of supports for additional rigidity.

It didn’t take me long until I was up on the bars testing them out. The width of bars felt just about perfect for dips which I was happy about. The small difference in bar height on the right side didn’t affect the usability of the parallel bars at all. The slight visual flaw does bother me a little bit but I’ll get over it.

Yesterday I finished the project off by applying two coats of water sealer to protect the wood from the blazing Florida sun.

In retrospect the two main hurdles were getting the 4 posts aligned properly and drilling PERFECTLY straight and level holes by hand. The straight hole thing could be addressed by a drill press. I was thinking an alternative for getting the posts aligned would be attaching a temporary, properly spaced 2×4 frame around the posts when it is out of the ground. Then you would leave that frame attached as you dig your holes and set level.

In total I spent around six hours on this project. Although it was definitely more challenging than building my pull up station, overall I am pleased with the outcome of my latest body weight exercise project. I am sure it will get many years of use. Feel free to send any questions or comments to me at duf@duf.net.

If you would like to see ALL the pictures from the construction process, go here

From Parallel Bars Construction, posted by Shawn Duffey on 4/02/2011 (22 items)

Generated by Facebook Photo Fetcher 2

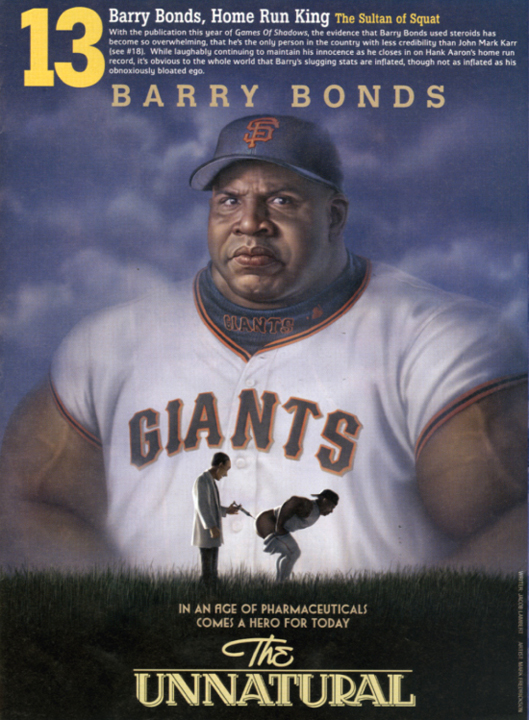

I don’t know who/what I am more disgusted with in the Barry Bonds trial. Barry Bonds is a f’ing asshole that cheated, got caught and refuses to admit it even though the entire world knows he is guilty. On the other hand you have the ridiculousness of the federal government literally spending millions of dollars to prosecute Bonds for lying about it.

I don’t know who/what I am more disgusted with in the Barry Bonds trial. Barry Bonds is a f’ing asshole that cheated, got caught and refuses to admit it even though the entire world knows he is guilty. On the other hand you have the ridiculousness of the federal government literally spending millions of dollars to prosecute Bonds for lying about it.