Perfect prints, Next tear down

Yesterday I loaded up one of the models I use for EUC stands into the Prusa slicer. With the extruder being a direct drive unit on this printer, changing filament color mid-print is very easy. I decided to include a filament change in the G-code which stops the printer right before the letters are printed so I can swap to a different color. I think the end result is super cool.

Yesterday I loaded up one of the models I use for EUC stands into the Prusa slicer. With the extruder being a direct drive unit on this printer, changing filament color mid-print is very easy. I decided to include a filament change in the G-code which stops the printer right before the letters are printed so I can swap to a different color. I think the end result is super cool.

The print came out fantastic and I’ll put them on the store as a premium version for a few more bucks since more is involved in their creation and they are printed on more expensive filament. The crazy thing about the MK3S is that although the print quality seems superior to all of my other printers, it completes the prints MUCH faster due to it’s use of top notch components. This piece normally takes over 9 hours on my other printers. The Prusa can do it in six and a half hours. I have a feeling that eventually, if 3D store sales support it, more Prusas could be joining the family down the road.

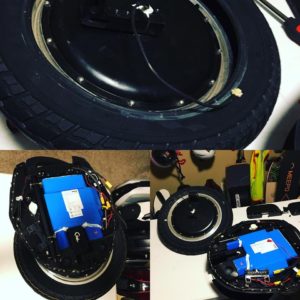

Now that my foldable table was cleared off from the printer build I put it back to work last night for the 16X tear down. Although I do not yet have a new inner tube for the tire I figured I could get a head start by tearing down the wheel to the point required to change a tire. The process was surprisingly simple compared to other electric unicycles, I was able to get the motor out after about only 15 minutes of work.

I also popped the tire off the rim, man that was tough as hell. The tire has minimal give, I can totally see why the tube got punctured when the tire was swapped. I had to pry my ass off with my huge tire levers. I may have to use my heat gun and a ton of lube to get the tire back on, hopefully without damaging the inner tube. The tube arrives Wednesday, I can hardly wait for the fun to begin.

I also popped the tire off the rim, man that was tough as hell. The tire has minimal give, I can totally see why the tube got punctured when the tire was swapped. I had to pry my ass off with my huge tire levers. I may have to use my heat gun and a ton of lube to get the tire back on, hopefully without damaging the inner tube. The tube arrives Wednesday, I can hardly wait for the fun to begin.